Engineering Precision Lab Automation with Monomer Bio

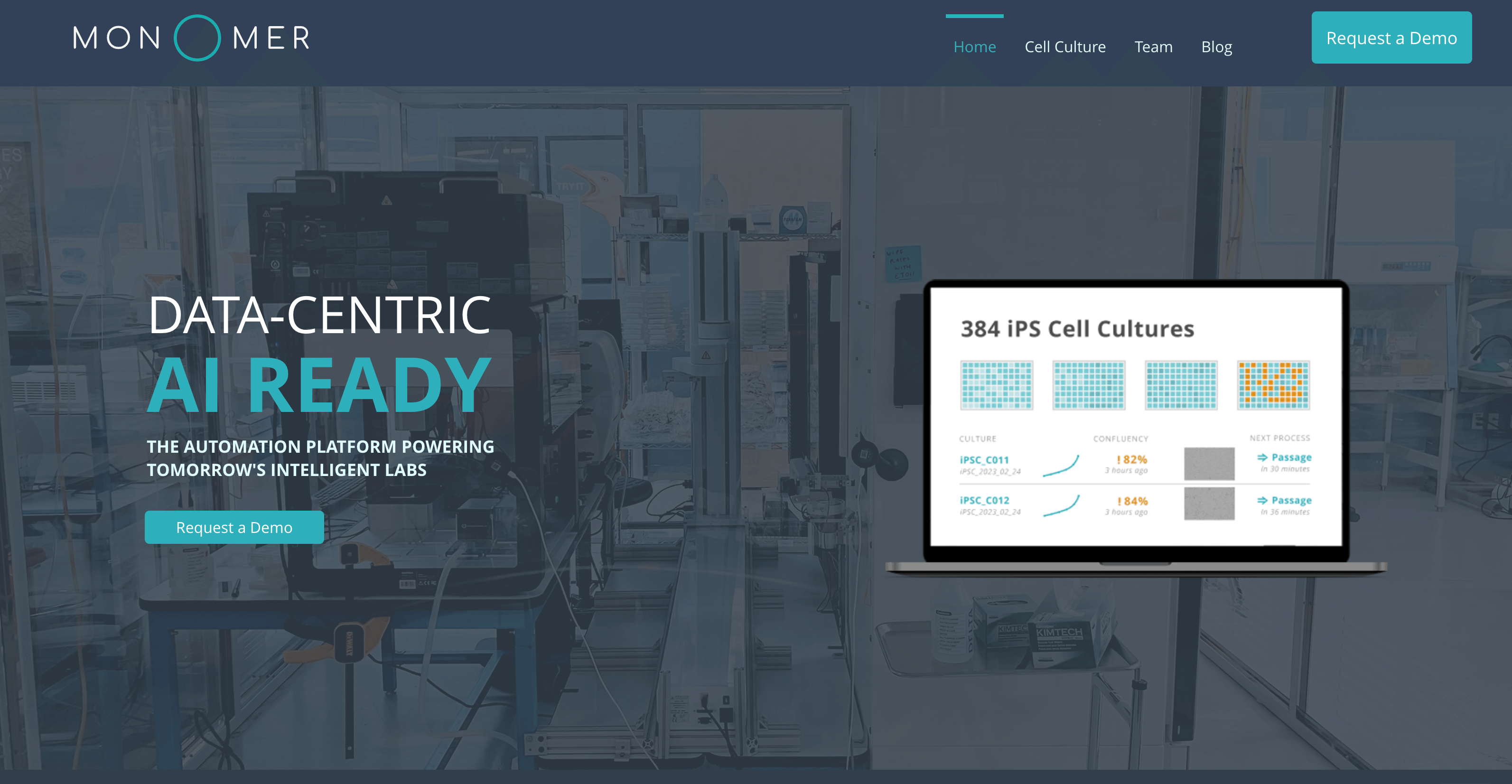

Monomer Bio, a forward-thinking lab automation company, faced a critical challenge: to develop an innovative tool that could accurately estimate the volumes of well plate wells using advanced technologies like computer vision and ultrasonics. This required a combination of deep technical expertise, keen understanding of bioinformatics, and experience with lab automation.

The unique combination of skill sets and prior experiences of their leadership team, including CEO Jimmy Sastra and CTO Mark Zhang, placed Monomer Bio in a strong position to tackle this ambitious project back in 2021. Still, they needed an expert consultant to turn their vision into reality.

Fortunately, they found their ideal consultant - an ex-Google machine learning engineer with a proven track record in applying representation learning for a Series A automated microscopy company. Having worked with several drug discovery companies, the consultant brought extensive knowledge of the sector’s unique challenges and opportunities.

Low Power Usage: The volume-estimation software had to be developed to operate efficiently with minimal power. At the very least this should be able to operate on a laptop with minimal-to-nonexistent GPU support, but ideally it would be transferable to an edge device.

Optical Property Variations: It had to adapt to changes in optical properties depending on the liquid contents of the well.

Accuracy: The solution needed to provide estimates with minimal error compared to actual measured amounts.

Uncertainty Quantification: It needed to quantify both the epistemic and aleatoric uncertainty of measurements, while offering recommendations on the types of input data or sensors that could further improve accuracy.

Info:

Efficient Design: The tool was designed to use computer vision and ultrasonics effectively while consuming minimal power. It wasn’t just enough to build a giant neural network and brute-force the solution. This required lessons taken from signal processing as well as pre-neural-network machine learning techniques.

Adaptability: It was built to adapt to varying optical properties due to changes in the liquid contents of the well.

Accuracy Enhancement: Advanced AI algorithms were used to reduce error and enhance accuracy. The training of the machine learning algorithms involved tailoring the loss penalties to give more weight to certain types of errors (the more unforgivable, the greater the penalty weight).

Uncertainty Handling: The solution incorporated innovative techniques to quantify both the epistemic and aleatoric uncertainty of measurements, and to offer recommendations for further improvements.

Based on the root mean squared error utility function, the inaccuracy of the tool on the test samples in a 96-well plate quickly approached ~2%. This is comparable to other commercially available (and more expensive) ratiometric photometry volume measurement systems. While more work was needed to ensure robustness on more sample types, this work had the added benefit of being much quicker to implement, build, and iterate further on.

Its ability to operate with low power, adapt to optical property variations, and quantify uncertainty, all while providing highly accurate measurements, was a significant achievement.